技术参数

Scan modules Measuring range in x,y-direction [mm] Resolution in x,y-direction [mm] Positioning range in z-direction [mm] Max. measuring speed [mm/s]

SC 50 50X50 0.5 100 50

SC 100 100x100 0.5 100 50

SC 150 150x150 0.5 100 50

SC 200 200x200 0.5 100 50

other dimensions on request

Sensors Resolution z [μm] Resolution x,y [μm] Working distance [mm] Measuring range in z-direction [mm] Camera (optional)

Confocal point sensor CF 4 0.02 1 4 1.0 off-axis

CF 13 0.02 1 13 1.0 (BMT5)

Autofocus sensor AF 2 0.025/0.0111) 1 2 1.5/0.651) integrated

AF 5 0.025/0.0111) 1 5 1.5/0.651) (BMT3)

Chromatic white light sensor CRT 52) 0.010 4 5 0.3 off-axis (BMT5)

CRT 122) 0.025 4 12 1.0

CRT 162) 0.075 8 16 3.0

Holographic sensor CP 15 3.0 12 12 1.8 integrated

(BMT 4)

CP 42 6.0 15 42 8.0

CP 65 10.0 25 65 18.0

1) with restricted measuring range 2) with 1, 4 or 30 kHz measuring frequency available

Modules

System controller High performance industrial PC, DVD-Writer, network card,

Windows XP Professional

Cabinet and work table MT 70 Stable container for electronic modules with work table

1550x800x750 (lxwxh in mm)

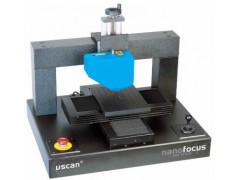

Granite measuring stand MP 100 Portal construction, 660x450x497 (lxwxh in mm) for SC 50 to SC 150

Granite measuring stand MP 200 Portal construction, 680x480x385 (lxwxh in mm) from SC 200

NF μsoft standard software NanoFocus control and evaluation software, profile and topography

representation, roughness calculation compliant with DIN EN ISO

Options

NF 3D-Plus Photo-realistic 3D presentation of topographical data (OpenGL)

NF Active X Interface modules to program individual measurement processes and

calculations (Excel/VBA)

NF Hybridmaster Automation tool for the use of μscan® in thick film production incl. SPC and

teach in module

NF Flatmaster Automated measurement of straightness, flatness and warpage

NF Solder Automated off-line measurement of fine pitch solderpaste print in SMT production

NF AutoScan Automated measurement of profiles and surfaces at arbitrary measurement

points

主要特点:

μScan采用模块化设计,特点是快速测量、不接触、不破坏、自动化

μScan的中心部件扫描模块(x/y方向样品扫描)可以和不同的传感器

(Z方向测量)连用,如Confocal point sensor、Autofocus sensor、

Chromatic white light sensor、Holographic sensor等。

AF2 自动对焦(Autofocus)

借由探测器的回馈讯号调整物镜位置,得到待测物焦点,而获得待测物的确实高度

CF4 共轭焦(Confocal, Laser)

激光光束经由物镜迅速上下移动聚焦于待测物上,此时偵测器能经由孔洞得到最大光的强度,如此侦测器根据此讯号确定其位置

应用

集成电路封装和表面贴片技术

厚膜混合电路:膜厚度的自动化测量

精密部件